Edge Computing and Industrial AI

Unified time-driven device state sampling, AI model inference, and industrial internet gateways for improved predictive maintenance and energy efficiency management accuracy.

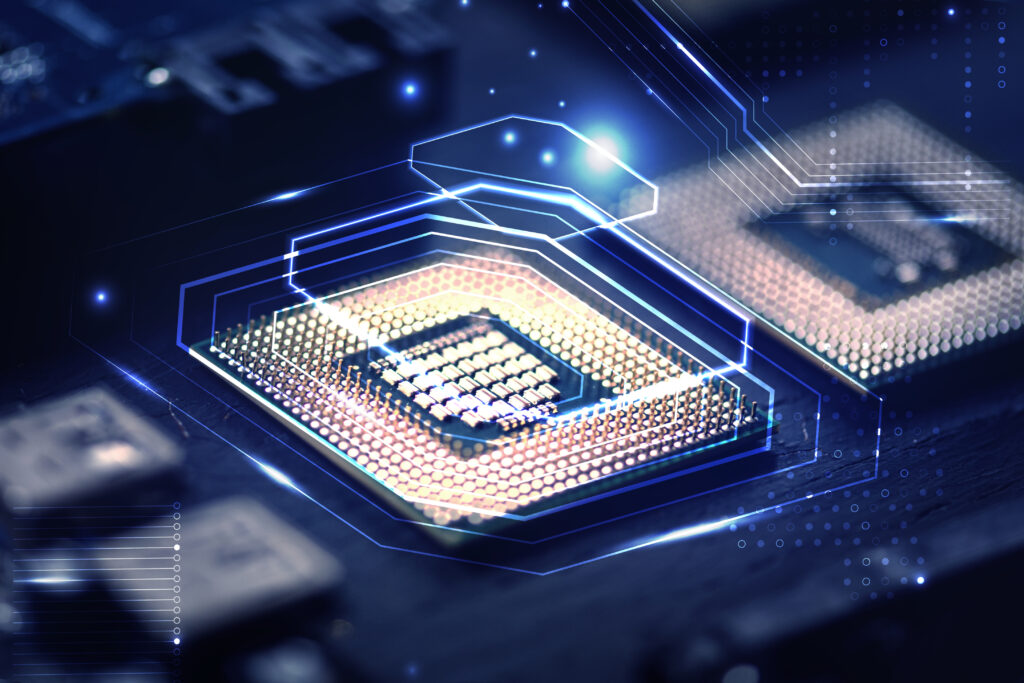

In the era of Industry 4.0, production lines, industrial robots, programmable controllers and edge computing devices need to work together under a unified time and frequency system. Beidou Bontec provides high-precision industrial clock solutions based on TSN, IEEE 1588v2 (PTP), 1PPS and 10 MHz standards, ensuring nanosecond synchronization from sensors, PLCs, robots to the host system, significantly optimizing latency certainty, system visualization, fault traceability and network collaboration, and realizing safer, more efficient and smarter production capacity.

Unified time-driven device state sampling, AI model inference, and industrial internet gateways for improved predictive maintenance and energy efficiency management accuracy.

Build highly reliable, low-latency, fault-tolerant industrial Ethernet to provide a secure synchronization foundation for distributed control systems.

The unified clock synchronizes SCADA control, process data collection and analysis platforms to improve production quality and safety control.

Precise time alignment of the bus to the controller via PTP and TSN ensures consistent motor control, valve regulation and edge measurement.

With nanosecond synchronization, robot movements are precisely coordinated with vision systems to improve processing, inspection and collaboration.